Sintered Filter unsur lilin Filter efficiency dhuwur

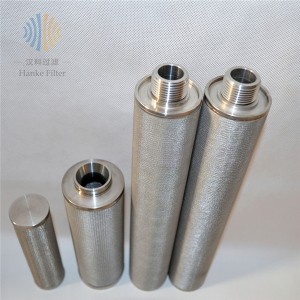

unsur Filter Sintered digawe saka bolong sintered utawa wêdakakêna ss minangka bahan mentahan.Sintered bolong punika jinis anyar saka materi Filter kang digawe saka limang-lapisan kabel stainless steel dirajut bolong dening proses "sintering", HFS Filter punika 1 -200 mikron.

Titik paling penting saka Filter felt sintered iku nomer akeh welding tliti dhuwur digunakake. Kanggo mesthekake roundness lan flat, kabel sintered bolong Filter cartridge wis sintered sawise nggunakake rolling proses welding lapisan lan cara koreksi las, iku bisa nggawe ing. sakabèhé katon luwih ayu.

Kaluwihan:

Bolongan seragam, tingkat filtrasi sing akurat

Atose dhuwur lan resistance abrasion apik

Resistance banget kanggo erosi, panas lan tekanan

Aplikasi:

Poliester

Pangolahan banyu segara

bledug penyaring pemurnian

Petrokimia, dehidrogenasi propana

Polysilicon, baterei solar

gas alam

Vulkanisasi

Farmasi, pemurnian minyak bumi

Ngombé, nyaring panganan utawa muter

Kontrol kualitas:

Riset lan pangembangan sing unggul

20 taun pengalaman

Ide desigh majeng

Proses produksi standar

Peralatan produksi lengkap

Manajemen kualitas sing efektif

Spesifikasi

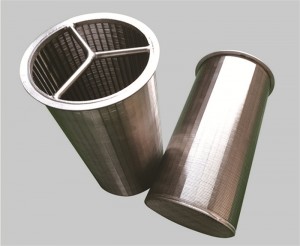

Sintered bolong (nambah siji lapisan 12mesh anyaman bolong, banjur dadi 6layers sintered bolong, resistance meksa bakal luwih sampurna)

|

Rating Filter Nominal (μm) |

Mesh Lapisan Proteksi |

Filtrasi Lapisan Mesh |

panyebaran |

Nguatake Layer Mesh |

Nguatake Layer Mesh |

kekandelan |

Permeabilitas Udara |

Tekanan gelembung |

Bobot |

Porositas |

|

1 |

200 |

400 x 3000 |

200 |

12 x 64 |

64 X 12 |

1.7 |

1.81 |

360 – 360 |

5 Lapisan |

Kira-kira |

|

2 |

100 |

325 x 2300 |

100 |

12 x 64 |

64 X 12 |

1.7 |

2.35 |

300-590 |

||

|

5 |

100 |

200 x 1400 |

100 |

12 x 64 |

64 X 12 |

1.7 |

2.42 |

260-550 |

||

|

10 |

100 |

165 x 1400 |

100 |

12 x 64 |

64 X 12 |

1.7 |

3.00 |

220-500 |

||

|

15 |

100 |

165 x 1200 |

100 |

12 x 64 |

64 X 12 |

1.7 |

3.41 |

200-480 |

||

|

20 |

100 |

165 x 800 |

100 |

12 x 64 |

64 X 12 |

1.7 |

4.50 |

170-450 |

||

|

25 |

100 |

165 x 600 |

100 |

12 x 64 |

64 X 12 |

1.7 |

6.12 |

150-410 |

||

|

30 |

100 |

400 |

100 |

12 x 64 |

64 X 12 |

1.7 |

6.86 |

120-390 |

||

|

40 |

100 |

325 |

100 |

12 x 64 |

64 X 12 |

1.7 |

7.10 |

100-350 |

||

|

50 |

100 |

250 |

100 |

12 x 64 |

64 X 12 |

1.7 |

8.41 |

90-300 |

||

|

75 |

100 |

200 |

100 |

12 x 64 |

64 X 12 |

1.7 |

8.70 |

80-250 |

||

|

100 |

100 |

150 |

100 |

12 x 64 |

64 X 12 |

1.7 |

9.10 |

70-190 |

||

|

150 |

50+100+50+30+30+100+50 |

2.0 |

25.00 |

50-150 |

||||||

|

200 |

40+80+40+20+40+80+40 |

2.0 |

26.00 |

50-150 |

||||||

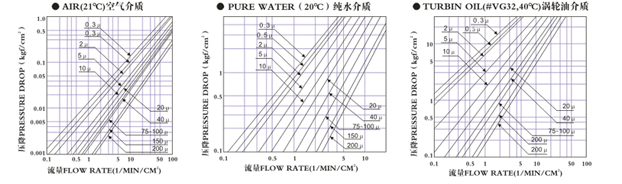

Kurva aliran tekanan diferensial

|

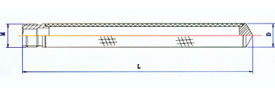

Model |

L |

D |

M |

Area Filter (M2) |

R |

Filter Media |

|

CF-14/65-R |

65 |

14 |

M10 * 1P |

0.002 |

2, 5, 10, 15, 20, 30, 40, 75 |

Kain Kawat Sinter Stainless Steel |

|

CF-14/250-R |

250 |

0.01 |

||||

|

CF-14/500-R |

500 |

0,022 |

||||

|

CF-14/1000-R |

1000 |

0.044 |

|

Model |

L |

D |

M |

Area Filter (M2) |

R |

Filter Media |

|

CF-25/250-R |

250 |

25 |

M20 * 1.5P |

0.019 |

2, 5, 10, 15, 20, 30, 40, 75 |

Kain Kawat Sinter Stainless Steel |

|

CF-25/500-R |

500 |

0.039 |

||||

|

CF-25/1000-R |

1000 |

0,078 |

||||

|

CF-30/500-R |

500 |

30 |

M20 * 2P |

0.046 |

||

|

CF-30/1000-R |

1000 |

0.093 |

||||

|

CF-30/1500-R |

1500 |

0.140 |

|

Model |

L |

D |

M |

Area Filter (M2) |

R |

Filter Media |

|

CF-50/250-R |

250 |

50 |

Sealing ring utawa flange |

0,038 |

2, 5, 10, 15, 20, 30, 40, 75 |

Kain Kawat Sinter Stainless Steel |

|

CF-50/500-R |

500 |

0,078 |

||||

|

CF-50/1000-R |

1000 |

0.150 |

||||

|

CF-60/500-R |

500 |

60 |

0.094 |

|||

|

CF-70/500-R |

500 |

70 |

0.108 |

|||

|

CF-75/500-R |

500 |

75 |

0.115 |

|||

|

CF-90/500-R |

500 |

90 |

0.140 |

|||

|

CF-150/500-R |

500 |

150 |

0.230 |

|||

|

Cathetan: Dhukungan njero unsur panyaring bisa dadi tabung perforated stainless steel utawa spring |

||||||

|

Model |

L |

D |

M |

Area Filter (M2) |

R |

Filter Media |

|

CF-16/390-R |

390 |

16 |

M16 * 1.5P |

0.02 |

2, 5, 10, 15, 20, 30, 40, 75 |

Web Serat Sintered Stainless Steel; |

|

CF-50/500-R |

500 |

50 |

0.07 |

|||

|

CF-63/750-R |

750 |

63 |

0.15 |

|||

|

CF-65/266-R |

266 |

65 |

0.05 |

|||

|

CF-70/500-R |

500 |

70 |

0.10 |

|||

|

CF-70/1000-R |

1000 |

70 |

0.21 |